Skive Tool Holder

Skive Tool Holder

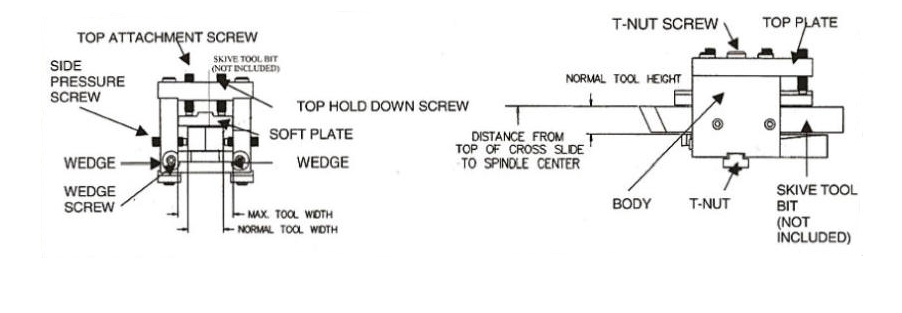

This holder can be used on either the front or back cross slide by changing the position of two nuts, so there is no need for two different holders. Among the salient features is the possibility of setting the tool within a few thousandths, if necessary, of the collet.

Also, this is the first holder to our knowledge that permits rolling the tool to correct or straighten diameters. Two tapered wedges, each individually adjusted, will raise or lower one side of the tool without affecting the other side. This eliminates shimming up the holder to get the correct diameters.

Standard stock screws are used almost entirely. A soft steel clamp plate is furnished. This plate sits on the skive tool and the lock screws tighten down on this plate. The blank tool is not furnished; however, it’s size can be determined from the table below.

Nonstock items. Price on application.

| Model | Skive 00 | Skive 0 | Skive 2 |

| Ordering Number | 130000 | 131000 | 132000 |

| Machine Size | #00 | #0 | #2 |

| Max Tool Width * | 1.110 | 1.500 | 2.100 |

| Normal Height to Center Line ** | 0.500 | 0.718 | 0.844 |

| *This can be increased but will not go through holder, thereby limiting useable tool length to length from holder to tip of tool. **To determine tool heights, subtract base radius of tool (smallest radius tools will cut part on) from normal tool height shown. | |||

| Replacement Parts | |||

| Body | 130001 | 131001 | 132001 |

| Top Plate | 130002 | 131002 | 132002 |

| Wedge Set (2 Reqd.) | 130003 | 131003 | 132003 |

| T-Key | 130004 | 131004 | 132004 |

| Top Screw (6 Reqd.) | 130005 | 131005 | 132005 |

| Side Screws (4 Reqd.) | 130006 | 131006 | 132006 |

| Bolts | 130008 | 131008 | 132008 |

| Soft Plate | 130010 | 131010 | 132010 |